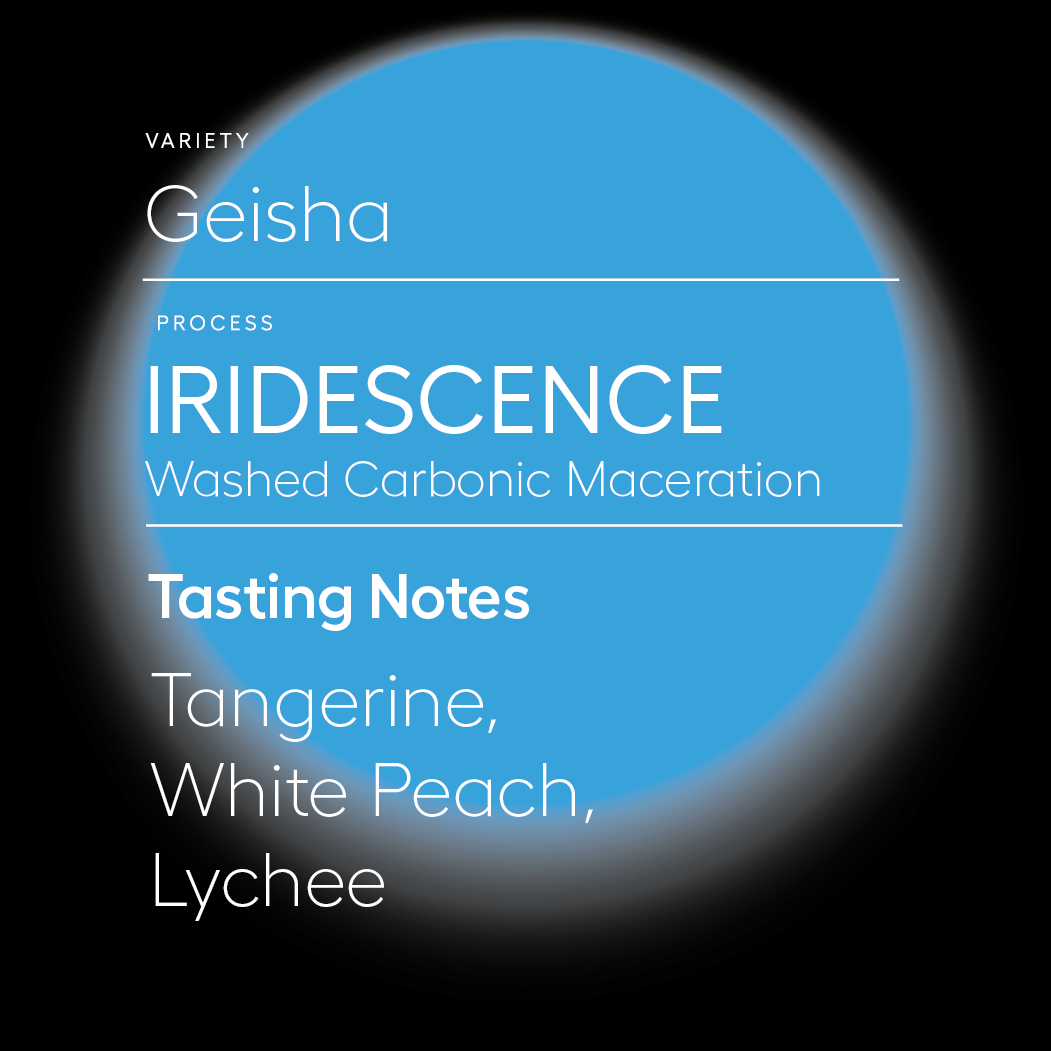

Iridescence | Geisha

Partner Producer Program

Savage Coffees has created the Producer Partnership Program (PPP).

Our program elevates the fruits of our fellow Producers through advanced processing techniques pioneered by Jamison. These multi-farm coffees showcase variety and terroir while celebrating trust through cooperation.

Process

Iridescence is a washed carbonic macerated Geisha grown in lush, volcanic, rainforest highlands. This anaerobic process was first pioneered by Jamison Savage in 2016, sparking a global coffee processing revolution, forever changing coffee production, around the world.

First, ripe cherries are hand harvested at more than 1650 m / 5400 ft. These cherries are then deposited into hermetically sealed tanks and periodically infused with CO2 allowing for a controlled fermentation of the fruit, thus enhancing the delicate flavors of tangerine, white peach, and lychee, coupled with elegant acidity, and high floral aromatics.

Roast Profile | Light

Flavor Notes ~ Balanced & well-bodied – notes of Coffee Flower, Lychee, Tangerine, Cane Sugar

Pickup available at St Petersburg

Usually ready in 24 hours

Iridescence | Geisha

100g

St Petersburg

2756 25th St N

St. Petersburg FL 33713

United States

Choose options